Share this post

AUCKLAND

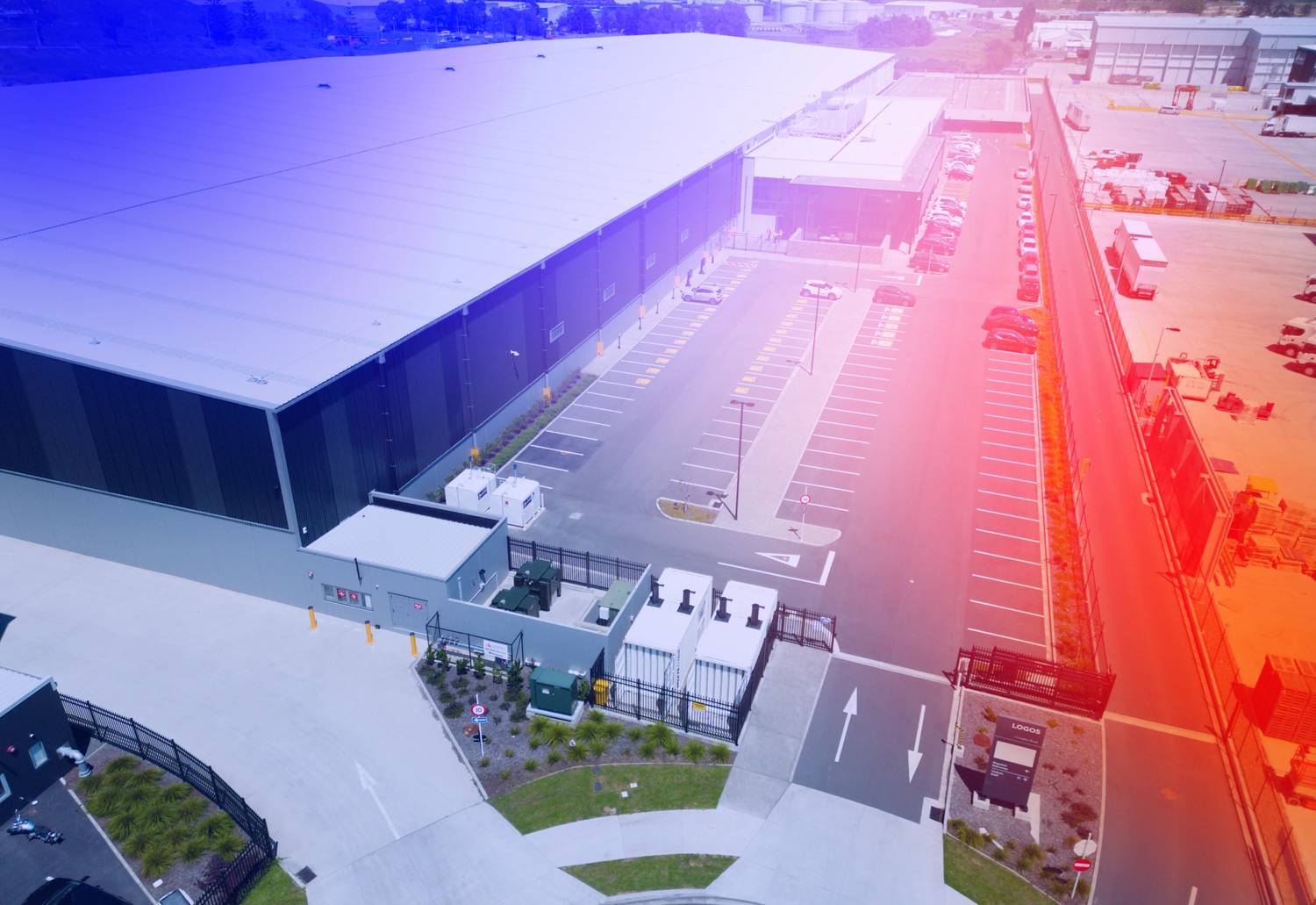

New Zealand Post unveiled the country's largest ever parcel processing facility in April 2024. Able to handle more than 30,000 parcels per hour at peak capacity, the Auckland Processing Centre (APC) is part of the postal operator's Te Iho program, which will enable NZ Post to become "the best delivery business for Aotearoa," according to CEO David Walsh.

Explaining the reasons behind the creation of the 30,000m² APC, Walsh says, "We saw the need to evolve as e-commerce continues to grow in New Zealand and internationally. In 2017, we committed a NZ$200m generational investment in parcel processing to ensure our success into the future."

"The APC is a key part of our aim to increase our parcel processing capacity to 190 million items per year by 2033. It is the third site to open under our strategic investment, after the Southern Operations Centre in Christchurch and the Wellington Super Depot."

Securing international items

The APC has been co-designed with the New Zealand Customs Service and the Ministry for Primary Industries (MPI). As a state-owned enterprise, NZ Post unsurprisingly has a very close relationship with these government departments.

Walsh explains, "NZ Post has a long history of working together with Customs and MPI. We've continued this collaboration in co-creating the international space at APC, investing in enhanced technology to improve the security and efficiencies of parcels entering and leaving New Zealand."

Both MPI and Customs are expected to move to the APC later this year ahead of the summer peak. Only then, when the international operations start, will the stated 30,000 parcels per hour at peak capacity be achieved.

"The facility is opening in a staged approach, starting with our domestic operations," Walsh adds. Once Customs and MPI join, the APC will act as a two-way processing gateway connecting New Zealand to the world, with an international freight service also part of the offer.

A need for automation

The significant investment in automation and technology at the APC has made it easier to see where parcels are in the network and has vastly reduced the need for manual handling.

Much of the hard graft in this area was undertaken by supply chain consultancy TMX Transform. The company had previously developed a 10-year transition roadmap and business case for Singapore Post, to reduce costs and meet future e-commerce demands. In the case of NZ Post, the business case was approved in November 2019.

"This followed a review of its network and identification of a need for automation," says Adam McDonald, TMX Transform's Head of Operations for ANZ.

Given the timeline, there were some challenges in delivering the facility and making it live.

Since the process started in late 2019, much of the build took place during the Covid-19 pandemic, which meant managing several areas, including the construction of the facility as well as the automation, despite the restrictions in place.

"NZ Post was also implementing new facilities in Christchurch and Wellington as part of the same Te Iho investment program. It is a testament to the program team who were able to manage the delivery of the two systems under difficult circumstances, facing an inability to travel or meet face-to-face on-site during lockdowns."

Mechanical complexity

Bringing domestic and international processing together in one unit is not an easy task. Domestic sorting began in April, with international outbound and inbound operations yet to come.

“This is still a work in progress, with the international system aiming to commence in late 2024,” continues McDonald.

It is an extremely complex system from a mechanical and sortation perspective. Beyond sortation, the system also manages the detection of biosecurity hazards and other threats to the border, through specialised scanners paired with traditional methods such as custom-made dog belts.

NZ Post also had one eye on sustainability. This was underlined by the government in its 'annual letter of expectation' to the business, in which it said that it expected NZ Post to join New Zealand's commitment to net zero emissions. The country's first Emissions Reduction Plan was published in May 2022.

For its part, NZ Post wanted to achieve a New Zealand Green Building Council (NZGBC) Green Star rating. Green Star is an internationally recognised voluntary sustainability rating system; for non-residential buildings, a rating of four-six stars can be awarded. The APC scored five.

NZ Post requested that several ESG initiatives were incorporated into the build, including gray water systems, use of low-VOC paint and water-efficient amenities. They worked collaboratively with the builder throughout the project to achieve this accreditation.

Once fully operational this summer, the APC should enable NZ Post to ramp up its parcel business. Walsh explains, “Our aim is to have a facility where once an item enters our network, it gets to where it needs to be on time and with care. Our investment in automation and technology at all our new sites aims to provide scalability, efficiency and improved customer service.”

The APC is a significant hub in that it is the latest step toward a national

automated network. “A key change is the move from a largely manual system at our International Mail Centre to APC,” continues Walsh. “With our domestic and international operations under one roof, it is expected to take around 10 minutes for an item to travel from international to inbound once it has been cleared.”

More investments

NZ Post is also investing in two new ‘super depots’ in Auckland that, along

with the APC, will service the national network as well as the Auckland metropolitan area. The Christchurch Processing Centre is the sister processing hub for the South Island, including the post’s commercial international business.

The combined infrastructure sets up the country for the future of parcel processing, especially as NZ Post is going to fold its mail network into its parcels business, using the same workforce to deliver both. This decision has been made in light of steadily falling mail volumes over the past two decades – from one billion items annually to just 220 million today, and an expected 120 million by 2028.

With Pitney Bowes forecasting that global parcel volumes will reach 225 billion by 2028, NZ Post will be well positioned to handle those numbers.

Hydrogen delivery

As part of its efforts to reduce emissions in its parcel delivery operations, NZ Post has been trialling a Hyundai zero-emission truck powered by hydrogen fuel cells.

The truck was launched in July 2022 for an initial evaluation period before being put into commercial operation. It is being used for parcel freight between Auckland and Hamilton, as well as around the South Auckland business area and between NZ Post’s South Auckland and Highbrook depots. Longer-range testing has been undertaken between the Highbrook and Waikato depots.

Based on typical heavy vehicle mileage, one fuel cell EV truck in operation avoids the equivalent CO2 of around 112 fossil fuel light vehicles – making a big difference with each heavy fuel cell vehicle.

According to the postal operator, heavy transportation experts from NZ Post and Hyundai Motors New Zealand have been evaluating the truck’s performance and are thrilled with the results on open-road and urban routes, paving the way for uptake of this new technology to reduce carbon emissions in the sector.

New, government-funded hydrogen refueling sites in Wiri, Te Rapa, Tauranga and Palmerston North will facilitate refueling in 15 minutes with state-of-the-art technology. These additional fueling sites will enable longer routes and 24/7 operations.

According to Grant Doull, national manager for hydrogen and eco commercial vehicles at Hyundai Motors New Zealand, New Zealand is the second country to adopt the technology in a commercial setting; Switzerland has 50 trucks in use.

“This project has been two years in the making,” Doull says. “This truck is ideal for NZ Post as a transporter of high-volume, lower-weight freight.” He adds that evidence and performance data gathered in the trial will be of value to everyone in the transportation sector.

“It’s been a valuable partnership with NZ Post, who are strong in sustainability leadership to trial this future-focused technology,” he concludes.

Te Iho Program

NZ Post’s 10-year Te Iho program to support the growth of the organization’s parcels business was launched in 2017. The planned NZ$200m (US$123m) has been described by CEO David Walsh as a “generational investment” aimed at transforming parcel processing.

As well as the new Auckland Processing Centre (APC), the project includes the Wellington Super Depot and the Southern Operations Centre, which

both opened in 2022. S&P Global Ratings Australia forecasts that in fiscal

2024, the post’s capital expenditure will reach NZ$129m (US$79.75m).

The spending reflects investments in parcel facilities that had likely increased NZ Post’s balance sheet debt obligations in 2022. However, the

ratings agency said at the time that it anticipated that the company’s leverage would reduce after June 2022.

S&P was generally positive about the Te Iho program, noting that its timely execution would lead to an increase in operational scale and efficiencies

of parcel processing and distribution capabilities.

The agency said, “A structural shift in e-commerce and sustained growth of the parcels business should lift margins. The growth in parcel volumes since fiscal 2020 has persisted and appears to be structural in nature, indicating longer-term changes in consumer purchasing patterns.”

In its most recent analysis at the end of 2023, the agency highlighted the structural decline in NZ Post’s letter business as well as “moderate parcel growth” and significant cost inflation. This, S&P said, “would weigh on the group’s earnings over the next 12 to 24 months”.

This article was written by Kevin Rozario and originally published in print and digital in Postal & Parcel Technology International's June 2024 edition.